|

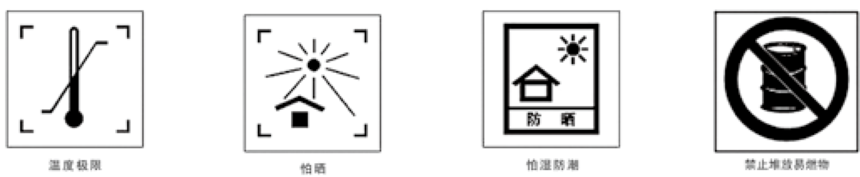

HOSE MAINTENANCEHOSE MAINTENANCE A hose and fitting maintenance program can reduce equipment downtime and maintain peak operating performance of the hydraulic system. Here are a few maintenance reminders. Hose assemblies should be inspected on a regular basis with frequency based on prior history of the equipment, a set maintenance/ inspection program, and the severity of the application or risk potential. Always use caution when inspecting hose assemblies. To reduce the risk of personal injury during system checkouts, do not touch the assembly and be aware of the potentially hazardous area surrounding the hose assembly. Inspect hose and fittings for the following : Exposed, broken, or corroded reinforcement wires. leaks in the hose or at the fitting. Cracked, damaged, or corroded fittings. Other signs of significant deterioration. If any of the above conditions exist, the hose assembly should be replaced immediately. The hydraulic system should also be inspected for the following: leaking ports. damaged or missing hose clamps, guards, or shields. Excessive dirt or grease on the assembly. Condition of system fluid, fluid temperature, contamination, and air entrapment. If any of the above conditions are found, appropriate corrective action should be taken. Functional tests should be conducted to determine if system are leak-free and operating properly. If hose assembly can be inspected and detached from the hydraulic system, additional steps can be taken to ensure a properly maintained assembly. With hose assembly detached, clean assembly by blowing out with clean, compressed air or rinsed with a compatible cleaning fluid. Inspect hose tube for cuts, obstructions, and cleanliness. Check layline of the hose to make sure the hose is not twisted. Check fittings to insure they are in good condition and properly crimped or attached to the assembly. If any of the above conditions are found, the hose assembly should be replaced. The hose assembly should be hydrostatically tested, using the approved test stands and procedures as outlined in SAE J1517. Test at proof pressure, or twice the working pressure of the hose, for 30 seconds to one minutes. When test pressure is reached, visually inspect the hose for any signs of weakness, leaks, or any hose movement relative to the fitting that would indicate a loose fitting. If any of these conditions exist, the assembly should be replaced. Specific hose assembly replacement intervals must be considered based on previous service life, government or industry recommendations, or when failures could result in injury risk or property damage. HOSE STORAGE Temperature, humidity, ozone, sunlight, oils, solvent, corrosive liquids, insects, rodents, and radioactive materials can adversely affect hose products and cause premature failures. Hose should be stored in a dark, dry atmosphere away from heat sources, electrical equipment, and the above adverse elements. The ideal storage temperature for rubber hose is +10¡æ to +20¡æ , with a maximum of 38¡æ .

|